ProCMP

Process-monitored CM and C polishing of optical components to achieve extremely high surface qualities

Background information

Project lead:

Hans-Christian Fritsch

Contact:

info@ilmsens.com

+49 3677 7613030

Project period:

July 2025 – June 2027

Cooperation partner:

Ilmsens GmbH

VM-TIM GmbH

EAH Jena

Funding Boby:

Freistaat Thüringen

Europäische Fonds für regionale Entwicklung (EFRE)

Funding code:

2025 VFE 0002

Cooperation project number:

1003666

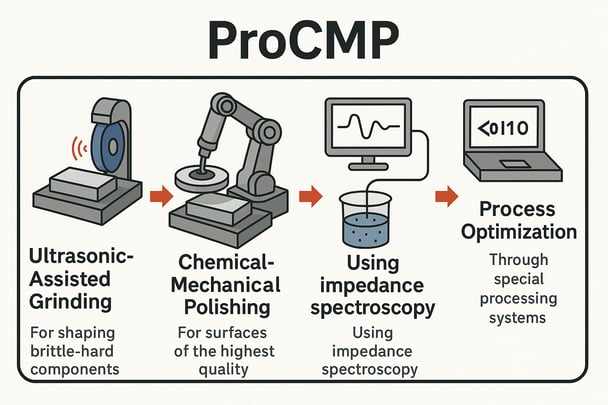

The ProCMP project is developing a new, highly efficient process chain for machining brittle-hard components. The aim is to achieve surfaces of the highest quality while optimising process efficiency.

After shaping using innovative processes such as ultrasonic-assisted grinding and ultra-fine grinding with resin-bonded diamond tools, the components are ground to a high-quality surface finish. After shaping using innovative processes such as ultrasonic-assisted grinding and ultra-fine grinding with resin-bonded diamond tools, chemical-mechanical polishing is carried out using a modern CNC-controlled 6-axis polishing system. By applying and optimising a wide range of polishing technologies (e.g. Synchro-Speed, A-WPT, A-FJP) in the field of chemical-mechanical polishing, both simple and complex surfaces can be processed in a time-efficient and highly accurate manner. For areas that are difficult to access, where conventional polishing methods reach their limits, a hybrid chemical polishing process with ultrasonic support is used. This ensures excellent surface quality in an efficient process.

Furthermore, the described polishing processes are subject to process control. At the heart of the process monitoring system is an impedance spectrometric system that continuously monitors the polishing agent suspension. The data obtained is evaluated using a special processing system, which not only provides a better understanding of the polishing process, but also allows it to be optimised in a targeted manner.